Spray Guns

Superior Quality. Lasting Performance.

GBP Distributing has been the exclusive U.S. distributor of WIDOBERG products for the last 30+ years. We offer several industry-leading Spray Guns noted below. We also offer current WIDOBERG users quality spare parts that hold up to the toughest of production environments. If you would like to discuss your specific Spray Gun needs, contact us today for a no-obligation consultation – and learn more about our Spray Gun Comparison Program.

Click Here to Read a letter from GPB Distributing’s Vice President, Bob VanSice.

WIDO-SPRAY™

The Wido-Spray high velocity spray gun out-performs any liquid compound applicator on the market.

Using compressed air within a spraying range of 60-100 PSI, the Wido-Spray controls airflow to the gun using a specially designed cylinder/piston assembly. This design allows the piston to compress compound and deliver it through a carbide spray nozzle at pressures of up to an incredible 1200 PSI. Click on the Price Quote button below to discover the savings and efficiencies of the Wido-Spray compound applicator.

HDP II (W-2222)™

Create a spray force of up to 2000 PSI with the HDP II from WIDOBERG.

A specially designed compression chamber allows normal shop air to deliver compound for deeper penetration, which results in longer life for your buffing wheel. In addition, its minimal throw-off allows for a cleaner work environment and incredible compound savings. Eliminate the need for expensive high-pressure pumping systems by investing in the HDP II today. It’s only from WIDOBERG and only delivered by GPB Distributing.

WIDOBERG Product Accessories & Spare Parts

Spare Parts

Order parts for your WIDO-SPRAY™

Order parts for you HDP II (W-2222)™

Accessories

VALVE CARTRIDGE

The Widoberg™ durable Valve Cartridge includes all wearing parts, which can be changed quickly.

NOZZLE EXTENSION KIT

For those hard-to-reach areas, Widoberg™ offers a unique Nozzle Extension Kit that comes complete with flexible extension.

WIDO-CONTROL 3

Monitor the operating functions of the Widoberg™ by using the Wido-Control 3 electronic control system. This system checks and indicates if a fault has occurred in any of the three spraying processes: It indicates if a nozzle is clogged, the check valve is leaking, the valve piston is blocked, there is no air, or insufficient compressed air.

BARREL-NOZZLE

Made with a special Tungsten Carbide alloy and fitted with a barrel-shaped orifice, the Widoberg barrel nozzle ensures a professional spray that is reliable and consistent. It’s capable of delivering both fine and abrasive material at many angles:

0, 5, 15, 25, 40, 50, 65, 95, 110 and 120 degrees.

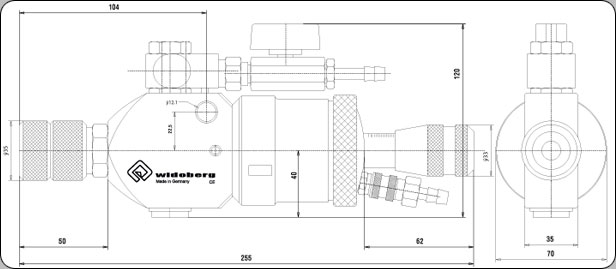

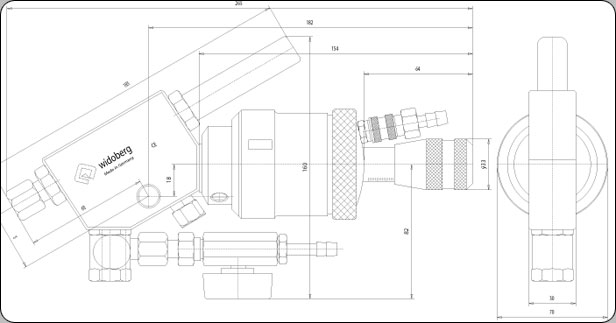

HDP_II_W-2222_Diagram.pdf

HDP_II_W-2222_Diagram.pdf